Specialized Supplies & Services

It’s more than just Oil, It’s Liquid Engineering!

WE STRIVE TO BE YOUR LIQUID ENGINEERING AND TECHNOLOGY PARTNER, CREATING INNOVATIVE SOLUTIONS FOR A WORLD IN MOTION.

Today

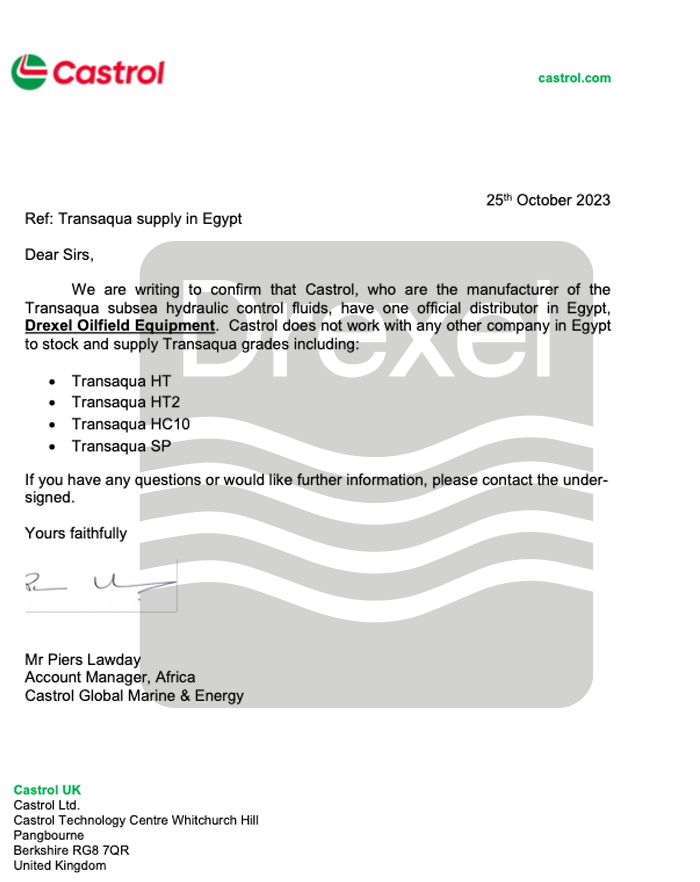

• Reliable operation of subsea hydraulic systems – Castrol Transaqua HT, HT2, DW, HC10

• Improved system protection subsea and for hardware storage on land – Castrol Transaqua SP

• Reliable operation of subsea boosting and compression – Castrol Brayco Micronic SBF E

• Reliable operation of subsea hydraulic systems – Castrol Transaqua HT, HT2, DW, HC10

• Improved system protection subsea and for hardware storage on land – Castrol Transaqua SP

• Reliable operation of subsea boosting and compression – Castrol Brayco Micronic SBF E

Tomorrow

• Subsea electrification

• Subsea boosting, water injection and compression

• Ultra deep water and deep water gas

• Carbon reduction and carbon capture and storage

• Integrated renewable power